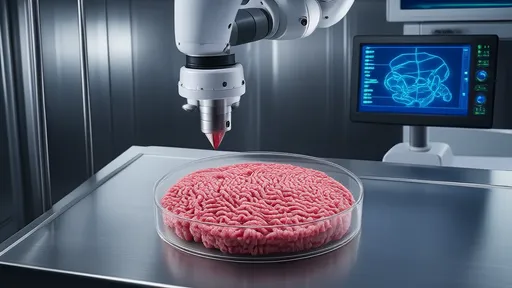

In a quiet laboratory in California, a team of food scientists gathers around a sizzling grill. The aroma filling the air is unmistakably that of cooking meat, yet the source is anything but traditional. What's sizzling on that hot surface represents one of the most significant technological advancements in modern food science: cultivated meat. After years of development and anticipation, the central question hanging in the smoky air is no longer just about its ethical or environmental promise, but something far more primal and immediate to the consumer experience. Can it truly satisfy the deep, culturally ingrained craving for the taste and texture of real meat?

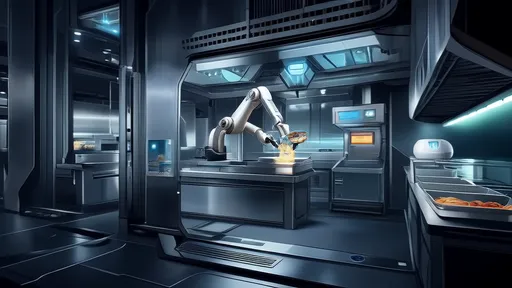

The journey of cultivated meat from petri dish to plate has been a monumental scientific endeavor. The process begins with a small biopsy taken from a living animal, harvesting muscle stem cells that possess the remarkable ability to multiply and develop. These cells are then placed in a bioreactor—a sophisticated cultivator that provides a warm, nutrient-rich environment mimicking the conditions inside an animal's body. Here, they are fed a broth of amino acids, sugars, salts, and vitamins, fueling their growth. Over weeks, these cells proliferate into billions, eventually forming muscle tissue that can be harvested, processed, and shaped into familiar forms like burgers, nuggets, or even more complex cuts like steak.

For the better part of a decade, the conversation around this technology focused on its potential to revolutionize our food system. The environmental benefits are staggering, with studies suggesting cultivated meat could require up to 95% less land and produce up to 92% fewer greenhouse gas emissions than conventional beef. The ethical implications are equally profound, offering a future where meat consumption doesn't necessitate animal slaughter. Yet, these powerful arguments always hit a fundamental wall: if it doesn't taste like the real thing, mainstream adoption will remain a distant dream. The taste, the texture, the entire sensory experience—what industry insiders call the "mouthfeel"—is the final and most crucial frontier.

To understand the challenge, one must first appreciate what makes meat, meat. The experience of eating a perfectly grilled steak or a juicy burger is a complex symphony of sensations. It begins with the Maillard reaction—the chemical interaction between amino acids and reducing sugars that gives cooked meat its savory, browned crust and rich, umami flavor. Then there's the texture: the initial resistance of the seared exterior giving way to the tender, fibrous interior. Fat is another critical player. Marbling—the white flecks of intramuscular fat within the muscle tissue—doesn't just contribute to flavor; it melts during cooking, basting the meat from within and creating that irreplaceable juiciness and mouth-coating richness. Replicating this intricate dance of chemistry and physics in a lab, without the biological structure of a living animal, is a Herculean task.

Early prototypes of cultivated meat, primarily in the form of ground products like burgers, faced significant hurdles. The initial focus was on growing muscle cells, but this alone resulted in a product that was lean, somewhat dry, and lacked the complex flavor profile of conventional meat. It was a proof of concept, but a far cry from a culinary delight. The texture was often described as "mushy" or "uniform," missing the fibrous pull of animal muscle. The flavor, while meaty, was one-dimensional, lacking the depth and complexity derived from fat, blood, and the various compounds that develop in an animal over its lifetime. It was, in essence, meat in its most basic form, and consumers accustomed to the rich sensory experience of a ribeye or a pork chop were unlikely to be swayed.

Recognizing this, scientists have embarked on a new phase of innovation, moving beyond simply growing cells to architecting the entire meat experience. The key breakthrough has been the development of co-culturing techniques for fat cells, or adipocytes. Companies are now growing fat tissue alongside muscle tissue, recognizing that fat is not just an add-on but a core component of meat's identity. This cultivated fat can be integrated into the muscle structure to create marbling, or processed into layers. The result is a dramatic leap forward in flavor and juiciness. When cooked, this fat renders and melts, releasing a burst of savory flavor and creating the moist, tender texture consumers expect. This focus on fat composition is arguably the single most important factor in closing the taste gap.

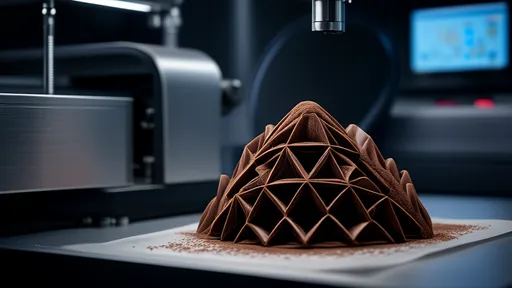

Texture, however, remains a formidable challenge, especially for whole-cut products like steaks or chicken breasts. Real muscle tissue isn't a homogenous paste; it's a complex architecture of long, aligned protein fibers bundled together by connective tissue. To replicate this, companies are employing advanced scaffolding techniques. These scaffolds, which can be made from edible plant-based polymers or even leftover biomass from agriculture like corn husks, provide a three-dimensional framework for the cells to grow on. They guide the muscle cells to organize themselves into aligned, fibrous structures that mimic the grain and chew of animal meat. The sophistication of these scaffolds is rapidly evolving, moving from creating ground meat analogues to attempting the complex, multi-textured experience of a whole muscle cut.

But the quest doesn't end with muscle and fat. The blood-like heme protein, famously used in plant-based meats, also plays a role in cultivated products, contributing to the metallic, savory notes of blood and the deep red color of raw meat. Furthermore, companies are exploring the cultivation of other cell types, such as connective tissue, to add even more layers of authentic texture. The ultimate goal is to create a full, structured product where different cell types work in harmony to deliver a complete and convincing meat experience.

So, what is the verdict from those who have tasted the latest prototypes? Culinary experts and food critics granted early access report a product that is lightyears ahead of its predecessors. The consensus is that for ground meat applications—burgers, meatballs, sausages—the latest cultivated products are achingly close to the real thing. The flavor is robust, savory, and undeniably meaty, with a satisfying juiciness thanks to the integrated fat. The texture, while perhaps not perfectly identical, is sufficiently close that in a blind tasting, many would be hard-pressed to identify it as not coming from an animal.

The real holy grail, however, remains the whole-cut steak. Here, the reviews are more measured but still remarkably optimistic. While the technology is not yet perfected, tasters describe products with a recognizable meaty flavor and a firm, chewy texture that provides resistance. It might not yet fool a seasoned sommelier slicing into a dry-aged porterhouse, but it is a staggering achievement that points unequivocally toward a future where it will. The gap is no longer a chasm; it's a narrowing fissure that scientists are confidently bridging.

Of course, the journey from a lab prototype to a product on supermarket shelves involves more than just taste. Scaling production to achieve cost parity with conventional meat is the next great hurdle. Regulatory approval from agencies like the FDA and USDA is a meticulous and necessary process to ensure safety. And perhaps the most intangible challenge is consumer acceptance—overcoming the "yuck factor" and building trust in a product that is biologically identical to conventional meat but born from a profoundly different process.

Yet, the progress on the sensory front is the key that unlocks everything else. Taste is the universal language of food, and it is the most powerful tool for convincing the world to embrace a new way of eating. The latest generation of cultivated meat is no longer a mere scientific curiosity or an ethical abstraction. It is becoming a genuine culinary product. It sizzles on the grill, it smells like dinner, and it delivers a satisfying, meaty bite. While it may not yet be a perfect replica in every single application, it has unequivocally proven that it can stand shoulder-to-shoulder with conventional meat. The question is no longer if lab-grown meat can mimic the real thing, but how soon it will become indistinguishable—and how quickly it will find its way onto our plates.

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025