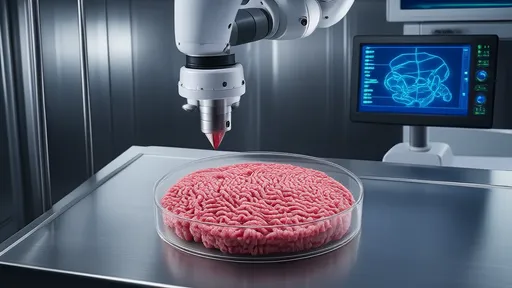

In the hushed, sterile laboratories of Silicon Valley, a quiet culinary revolution is brewing. It doesn't involve a celebrity chef wielding a gleaming knife or a farm-fresh ingredient. Instead, it involves a hum, a whir, and the precise, layer-by-layer deposition of edible materials. This is the world of 3D printed food, a technology that promises to fundamentally reshape our relationship with what we eat, moving it from the realm of artisanal craft to digitally programmable sustenance. The question echoing through boardrooms and kitchens alike is whether this represents a fleeting gimmick, a toy for the tech-obsessed, or the genuine future of global nutrition.

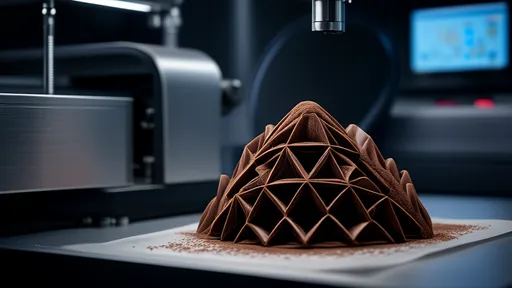

The core technology, known as additive manufacturing, is astonishing in its application to organic matter. Unlike traditional subtractive methods like carving or milling, 3D printing builds objects from the ground up. Food printers employ specialized syringes, each loaded with a food-based "ink" or paste—think chocolate, cheese, hummus, pancake batter, or even pureed meats and vegetables. A digital blueprint, a CAD file for your dinner, guides a nozzle as it deposits these materials with microscopic precision, building a three-dimensional edible object one minuscule layer at a time. The result can range from a simple geometric cookie to an intricately lattice-worked sugar sculpture that would be impossible to create by human hand.

For culinary artists and high-end restaurateurs, this technology is nothing short of a revelation. It unlocks a new dimension of creativity, allowing for previously unimaginable presentations and textures. Imagine a dessert that looks like a coral reef, with delicate, edible structures that melt on the tongue, or personalized chocolates with a customer's portrait rendered in stunning detail inside the candy itself. This is where the technology currently shines brightest, in the domain of the spectacular and the bespoke. It is the ultimate tool for creating edible experiences that are as much a feast for the eyes as for the palate.

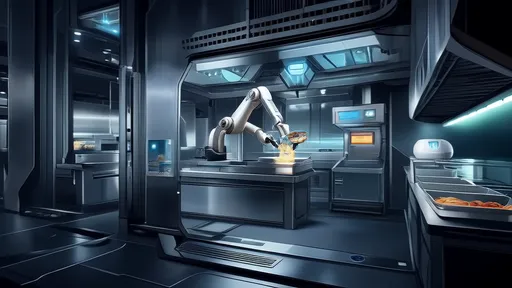

However, to dismiss 3D printed food as merely a tool for gourmet spectacle is to overlook its profound potential to address some of humanity's most pressing challenges. The global population is soaring, arable land is diminishing, and climate change threatens traditional agriculture. In this context, 3D food printing emerges not as a novelty, but as a potential lifeline. Its true power lies in its unprecedented efficiency and personalization. Imagine a future where nutrient pastes, derived from sustainable and alternative protein sources like algae, insects, or lab-grown meats, are the primary ingredients. These unappetizing base materials could be transformed by a printer into familiar and appealing shapes—a steak, a piece of fish, a vegetable medley—tailored to an individual's exact nutritional requirements.

The implications for health and wellness are staggering. For the elderly or those with dysphagia (swallowing difficulties), pureed diets are often unappealing and monotonous. A 3D printer can take that same nutrient-rich puree and reform it into the shape of a juicy steak or firm broccoli floret, restoring dignity and pleasure to mealtimes. For athletes, a printer could produce meals calibrated with exact ratios of protein, carbs, and electrolytes for optimal performance and recovery. For those with specific allergies or dietary restrictions, every single ingredient can be controlled and accounted for, eliminating the risk of cross-contamination and ensuring complete dietary safety.

Beyond individual health, the technology promises a radical reduction in food waste and supply chain inefficiencies. Traditional food production is notoriously wasteful; a significant portion of produce never leaves the farm due to cosmetic imperfections. With 3D printing, "ugly" fruits and vegetables can be pureed and used as perfect printing ink. Food can be printed on-demand, in the exact quantities needed, eliminating spoilage in home kitchens and restaurants. Long, complex, and carbon-heavy supply chains for certain foods could be shortened to the distribution of compact, shelf-stable nutrient cartridges.

Of course, the path to this futuristic vision is littered with significant obstacles. The most immediate hurdle is the "yuck factor." The concept of eating something that originated as a paste in a cartridge is a major psychological barrier for many. Food is deeply cultural and emotional; we crave the sizzle of a grill, the aroma of fresh bread, the irregular beauty of a hand-picked apple. Can a printed meal, no matter how nutritious or perfectly shaped, ever replicate the soul of cooking? The technology also currently struggles with replicating the complex textures and mouthfeel of many whole foods. Printing a visually perfect steak is one thing; replicating the fibrous tear and juiciness of a prime cut is a monumental engineering challenge that remains largely unsolved.

Furthermore, there are serious economic and societal questions. Will this technology democratize nutrition or create a new divide between those who eat "real" food and those who consume printed sustenance? The cost of printers and specialized ingredients, for now, places them firmly in the realm of professionals and the wealthy. There are also regulatory mountains to climb. How will agencies like the FDA regulate the safety of these printing processes and the novel ingredients they might use? Establishing a framework for safety and labeling will be a complex and necessary process before widespread adoption can occur.

So, is it a gimmick or a revolution? The answer is that it is currently both. In its present incarnation, it is a powerful and fascinating gimmick, dazzling us with its possibilities in boutique applications. But to see only the gimmick is to be shortsighted. The underlying promise—the ability to create efficient, sustainable, and hyper-personalized nutrition—points unequivocally toward a revolution. It may not replace the joy of a home-cooked meal or the artistry of a master chef, but it doesn't have to. Its role may be to become the quiet, reliable backbone of a new global food system, addressing the pragmatic needs of a hungry planet while freeing up "real" food for cultural and celebratory purposes.

The hum of the food printer may soon become as familiar as the ring of a microwave. It represents a fundamental shift from growing and cooking to programming and printing. The journey from a tech demo to a kitchen staple will be long and fraught with challenges, but the potential rewards—a healthier, more sustainable, and waste-free relationship with what we eat—make it a pursuit worthy of our most serious consideration. The future of food may not be found in a field, but in a digital file.

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025