In the realm of personal protective equipment, the humble face mask has become an indispensable part of daily life. While much attention is given to filtration efficiency and breathability, one often overlooked yet critical component is the nose wire or nasal strip. This slender, malleable strip embedded along the top edge of the mask plays a pivotal role in achieving a proper seal, a factor that significantly influences the overall effectiveness of the mask. Without a secure fit around the nose and cheeks, air—and any potential contaminants—can easily bypass the filtration layers, rendering even the most advanced mask materials less effective. Understanding and mastering the art of shaping this nose wire is therefore not a mere detail, but a fundamental aspect of responsible mask usage.

The primary purpose of the nose wire is to bridge the gap between the rigid structure of the mask and the unique, often irregular, contours of the human face. No two nose bridges are identical; they vary in height, width, and shape. A flat, un-molded mask will inevitably leave gaps on the sides of the nose, a common sight that indicates a compromised fit. When you properly shape the wire to conform to the exact profile of your nasal bridge, you create a custom seal. This action physically blocks the main pathway for unfiltered air to escape from the top of the mask or for external droplets to enter. It is the first and most crucial step in ensuring that the air you breathe is forced through the mask's filtering media, as intended by its design.

Before you even begin to mold the wire, the initial step is to ensure the mask is positioned correctly. Hold the mask by the ear loops or ties and place it over your nose and mouth. The nose wire should be sitting precisely at the top, aligned with the bridge of your nose. This might seem obvious, but a misaligned wire—too high or too low—will make it impossible to achieve an optimal seal, no matter how well you shape it afterward. Gently pull the bottom of the mask under your chin to ensure full coverage. This correct positioning provides the foundation upon which you will mold the wire, setting the stage for a successful fit.

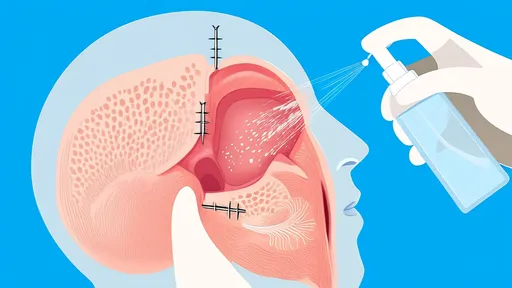

The actual shaping process requires a deliberate and gentle touch. Using the pads of your index fingers—not your fingernails, which could potentially puncture the mask material—press down firmly on the outside of the mask, tracing the outline of the nose wire. Start from the center of the bridge and slowly work your way outward toward your cheeks. The key is to apply consistent pressure along the entire length of the wire, coaxing it to bend and conform to the specific slopes and curves of your nose. You are not just pinching the center; you are sculpting the entire strip to create a seamless, gasket-like effect. You should feel the wire resisting slightly before it holds its new shape. This process typically takes a few seconds of focused pressure but makes a world of difference.

For individuals who wear glasses, a properly shaped nose wire is not just a matter of efficacy but also one of practical comfort. The most common complaint among bespectacled mask-wearers is foggy lenses, a direct result of warm, moist exhaled air escaping upward from the top of the mask and condensing on the cooler surface of the glasses. A meticulously molded nose wire eliminates this escape route, sealing the air inside the mask and directing it downward or through the filter material. Consequently, your vision remains clear, which is especially important in professional settings or while performing tasks that require visual precision. This simple act of shaping the wire enhances both safety and daily convenience.

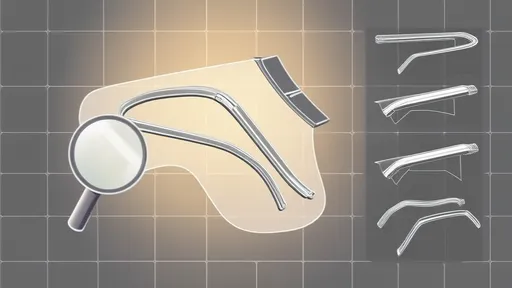

It is important to recognize that not all nose wires are created equal. Masks come with a variety of wire types, each with different properties. Some are made of thin, pliable aluminum, which is easy to shape but may lose its form over time or with repeated adjustments. Others use a sturdier, plastic-coated metal that offers more resilience and memory, holding its shape through multiple wears. There are also masks with a foam-backed bridge instead of a wire, designed for comfort and to reduce pressure marks, though these may require a slightly different fitting technique. Understanding the material you are working with allows you to apply the appropriate amount of pressure—softer for delicate wires, firmer for robust ones—to achieve the desired seal without damaging the component.

Even after a perfect initial shaping, the fit can be compromised throughout the day. Natural facial movements—talking, smiling, eating, or drinking—can subtly shift the mask. Furthermore, putting on and taking off the mask, even carefully, can alter the wire's shape. This makes periodic checks and minor adjustments a necessary habit. Every so often, especially after a mask removal, take a moment to reassess the seal around your nose. Cup your hands around the edges of the mask and exhale sharply. If you feel air rushing out from the top near your eyes, the seal has been broken and the wire needs to be reshaped. This quick check takes mere seconds but ensures continuous protection.

For some, achieving a perfect seal can be challenging due to facial hair, very low or high nasal bridges, or sensitive skin. In these cases, additional strategies can complement the nose wire's function. Double-sided mask tapes or strips can be applied to the skin on the cheeks and bridge of the nose, providing an extra adhesive seal that anchors the mask in place. Alternatively, mask fitters or braces—small, frame-like devices worn over a mask—can help press the edges of the mask snugly against the face. While these are helpful aids, they work best in tandem with a well-shaped nose wire, not as a replacement for it. The goal remains the same: to eliminate gaps and ensure all inhaled and exhaled air is filtered.

In conclusion, the act of pinching the nose wire on a face mask transcends a simple routine; it is a critical skill that directly impacts personal and public health. It is the difference between assuming you are protected and knowing you are. By taking those few extra seconds to carefully mold the wire to the unique landscape of your face, you actively enhance the mask's performance, protect yourself and others more effectively, and contribute to a culture of meticulous and responsible safety practices. In the ongoing effort to maintain public health, such attention to detail is not just recommended—it is essential.

By /Aug 26, 2025

By /Aug 26, 2025

By /Aug 26, 2025

By /Aug 26, 2025

By /Aug 26, 2025

By /Aug 26, 2025

By /Aug 26, 2025

By /Aug 26, 2025

By /Aug 26, 2025

By /Aug 26, 2025

By /Aug 26, 2025

By /Aug 26, 2025

By /Aug 26, 2025

By /Aug 26, 2025

By /Aug 26, 2025

By /Aug 26, 2025

By /Aug 26, 2025

By /Aug 26, 2025

By /Aug 26, 2025

By /Aug 26, 2025